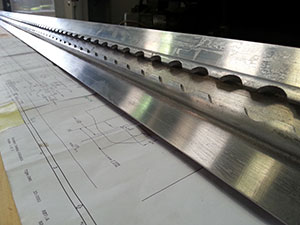

An insight to the machinery and equipment we run.

At DS Machining, we have a well equipped Milling section, consisting of the following machines.

We offer:

The Haas machines offer axes traverse up to 1500mm in the X axis, 10,000 RPM, 24m/min Rapid, 30 tool A.T.C and fully programmable fourth axis. These machines have the capability of producing large batch quantities quickly, ensuring quality and consistency from the first to the last of the batch. They are connected to our offline programming and CadCam station.

December 2019 saw us remove the aging Haas VF4 and replace it with the XYZ HD1100. This heavy duty beast of a machine is smaller in the X axis than a VF4, but has a bigger Y axis and more room under the spindle. It uses the Siemens ShopMill software and is 4th axis and ONECNC compatible.

We also have 2 off XYZ LPM Vertical CNC Machining centers. A full 3 axis CNC, it is coupled to XYZ's PMX Conversational control, which is simple to use and fully compatible with our ONECNC CadCam package. BT40, 8000rpm, 16 tool ATC and 20m/min rapid, make it a solid workhorse and we are very please with the results we are achieving with them.

Our biggest X axis capacity comes from our DPM 5000, which has 1500mm. This machine has an XYZ Prototrak MX3 Control which offers conversational style 3 Axis programming. These machines allow us to produce complex milled components in low volume, with significant improvement in quality and productivity over a conventional machine. We have some conventional mill machines too.

For the production of larger batches of turned components, we have a choice of three machines.

The HAAS SL30 is a CNC lathe with 65mm bar capacity. It has a 10" chuck and Driven Tooling, making it very versatile with regard to the components that it can produce. Our HAAS SL10 which is slightly smaller is capable of short bar work up to 45mm max capacity and small billet work.

In 2019 we increased our CNC Turning Capacity to 3 machines. Staying with the Haas machines we added the TL15, a bar fed lathe with 65mm bar capacity, C Axis and Driven tools. It has given us back up for our other 2 lathes and provides us options for manufacture that we didn't have previously.

All HAAS machines are linked to an offline programming and CadCam station. Having both sizes of HAAS machines, makes our turning capacity quite versatile. By being efficient with their use, we can get thru a lot of work quickly. The bar feeds give us a lights out option for manufacture as well.

All three of our HASS machines are geared up for large volume production of turned parts between, say, 20 and 1000 off.

For lower volume production of parts, we again have a choice of two machines.

An XYZ VL425 with advanced Prototrak SMX Control offers the latest in Centre Lathe Turning Technology. Based around the conventional lathe, it offers a conversation style of control with constant surface speed and user friendly operation. This makes it capable of full CNC quality machining on small batches, with a fraction of the set up time. The XYZ VL425 is also capable of producing larger turned parts, up to 650mm in the gap, and 450mm over the bed, with 2 meters between centers.

We also have a smaller version of this machine. The XYZ SLX 1630 is similar in all aspects, however, is much better suited to the smaller jobs that are sometimes found lost on the bigger machine. The XYZ SLX 1630 exhibits all the easy to use attributes for speedy production of one offs and small batch work. This ensures jobs are carried out as quickly and cost effectively as possible. It has a swing over bed of 400mm, and this spindle bore size of up to 54mm.

Our XYZ 555 lathe has been a game changer for us with regards to adding to our turning capacity for low volume parts. It's impressive 102mm spindle bore clearance and chuck clearance over the bed and saddle will be particularly useful for the work that we undertake. XYZ Lathes have served us well in the past and it looks like they will continue to do so in the future.